Equipment & Process Reliability Testing in Predictive Maintenance Testing

Anticipate failures before they happen with our advanced predictive testing tools that keep your operations running smoothly and efficiently.

Overview

Predictive Maintenance Testing for Equipment & Process Reliability Testing by Manufacturing EnviroTest provides organizations with the tools they need to forecast mechanical issues and reduce unplanned downtime. By analyzing operational data in real-time and applying predictive analytics, our solution identifies patterns and deviations that precede equipment failure. This allows for proactive maintenance scheduling, increased operational continuity, and reduced total cost of ownership.

Headquartered in Seattle, WA, Manufacturing EnviroTest is a trusted provider of innovative, reliable B2B solutions for predictive maintenance across North America. Backed by advanced R&D, stringent quality control, and collaborative partnerships with industry leaders like GAO Tek and GAO RFID, we help our clients create resilient, intelligent, and scalable maintenance strategies tailored to their operations.

Hardware

Industrial-grade IoT sensors (vibration, thermal, pressure, current)

Use Industrial & Asset Monitoring Sensors from IoT sensors for real-time measurement of mechanical and electrical parameters to ensure system reliability.

Wireless gateways and edge processing units

Deploy LoRaWAN Gateways from LoRaWAN to enable long-range, low-power connectivity for dispersed industrial sensor networks.

Smart data acquisition modules

Leverage Ethernet Testers from Ethernet to collect, transmit, and validate data streams from embedded systems during test operations.

Embedded diagnostic controllers for integration

Apply Device Edge from Edge Computing for local processing of diagnostics to enhance operational resilience.

Core Components

Software

Predictive analytics engine powered by AI/ML

Maintenance event tracking and automation platform

Interactive dashboards for machine condition visualization

Workflow tools for task prioritization and resource planning

Cloud Services

Centralized cloud data storage and analytics

Historical performance trend monitoring

Secure remote access and diagnostics

Integration with enterprise asset management systems

Key Features and Functionalities

Real-time monitoring with condition-based thresholds

AI-driven failure predictions and alerts

KPI dashboards for health scoring and asset prioritization

Cloud-integrated predictive modeling

Root cause analysis and repair recommendation engine

Scheduled maintenance automation and reporting

Benefits

Reduces unplanned downtime and emergency repairs

Extends the lifespan of machinery and equipment

Optimizes spare parts inventory and labor allocation

Enhances operational efficiency and productivity

Enables data-informed decision-making for asset management

Lowers total maintenance and operational costs

Industries Served

Automotive & Aerospace

Energy & Utilities

Manufacturing & Assembly

Pharmaceuticals & Chemicals

Food & Beverage

Transportation & Logistics

Integrations and Compatibility

Maintenance Platforms : IBM Maximo, SAP PM, Oracle CMMS

Development Frameworks : NI LabVIEW, Python, MATLAB

Communication Protocols : MQTT, OPC-UA, Modbus TCP, Ethernet/IP

Cloud Ecosystems : AWS IoT, Microsoft Azure, Google Cloud

Applications

Heavy manufacturing and discrete production

Utilities infrastructure (power, water, gas)

Transportation systems and fleet management

Food processing and packaging machinery

Mining and extractive industry equipment

Data centers and HVAC systems

Relevant Industry Standards

ISO 17359

ANSI/ISA-18.2

IEEE 1233

CSA C282

ASTM E1316

NEMA MG1

Case Studies

United States – Michigan

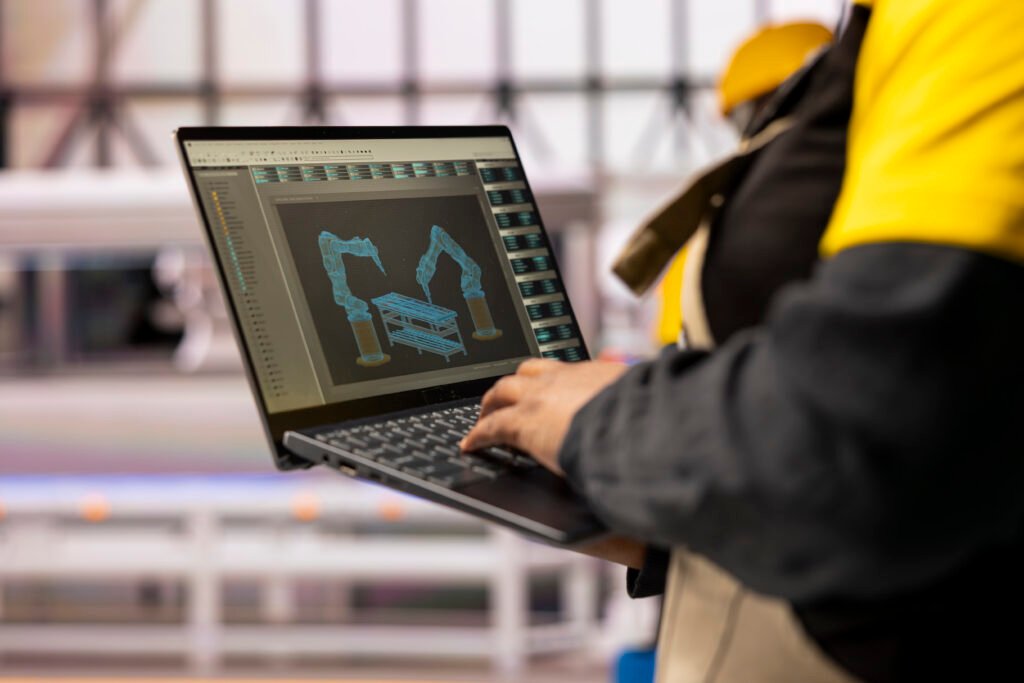

An automotive parts manufacturer in Michigan deployed our predictive maintenance platform to monitor robotic welding systems. Within two months, it prevented two potential motor failures, reducing unplanned maintenance hours by 30% and increasing line efficiency.

United States – North Carolina

A textile plant in North Carolina adopted our condition-based monitoring system for high-speed looms. Predictive alerts helped schedule maintenance two weeks in advance, avoiding expensive line shutdowns and saving an estimated $80,000 annually.

Canada – Alberta

A gas utility provider in Alberta integrated our predictive diagnostics into their compressor stations. Using vibration and thermal sensor data, our platform flagged a failing coupling bearing, preventing a catastrophic failure and enhancing their maintenance planning.

Looking to ensure your products perform flawlessly from the very first use?

Manufacturing Envirotest is ready to support your journey with expert functional testing solutions tailored to your industry and goals. Contact us today for personalized consultations, service inquiries, or to get started with a custom testing solution built around your needs.