Equipment & Process Reliability Testing in Tooling Wear and Tear Analysis

Prevent unexpected failures and optimize maintenance schedules with precise tooling wear diagnostics and lifecycle insights.

Overview

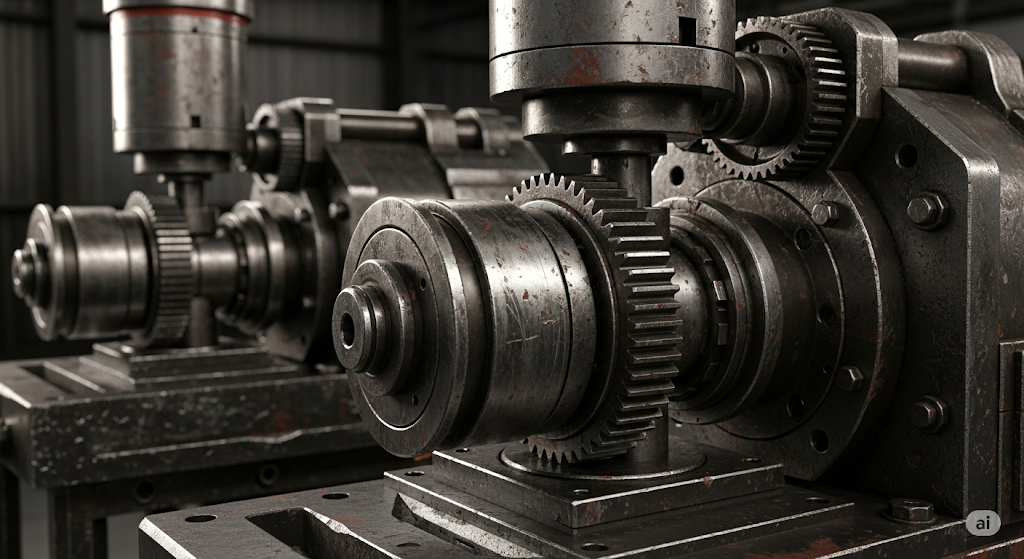

Tooling Wear and Tear Analysis for Equipment & Process Reliability Testing by Manufacturing EnviroTest delivers detailed insights into the condition, lifespan, and performance degradation of cutting tools, dies, molds, and other precision components. This system helps manufacturers proactively identify early signs of wear, schedule preventive maintenance, and minimize downtime due to tool failure. Our cutting-edge approach integrates sensor-based data collection, software modeling, and cloud analytics to ensure the highest levels of accuracy and repeatability.

Hardware

Core Hardware Components

On-machine sensors for vibration, temperature, and force monitoring

Use Industrial & Asset Monitoring Sensors from IoT Sensors to detect and track wear indicators directly on production tools.

Tool wear measurement microscopes and optical scanners

Integrate Optical & Imaging Sensors from IoT Sensors for high-precision visual analysis of tool surface degradation.

Precision profilometers and contact gauges

Apply Surface Roughness Gauges & Testers from Structural Testers for micro-level assessment of surface profile changes.

High-speed imaging systems

Use CCTV & Video Equipment from CATV / CCTV to capture detailed high-frame-rate footage of tool impact and erosion patterns.

Data acquisition (DAQ) modules for real-time tracking

Employ Device Edge units from Edge Computing for localized, real-time data collection and analytics at the machine level.

Core Components

Software

Tool life modeling and predictive analytics engines

Edge computing software for sensor signal processing

Data visualization dashboards

Maintenance alert systems and wear progression simulators

Integration-ready tool monitoring APIs

Cloud Services

Centralized tool wear data storage and lifecycle tracking

AI-powered analysis for anomaly detection

Cross-site comparison for standardized maintenance metrics

Scalable access across global operations via secure cloud infrastructure

Key Features and Functionalities

Real-time tool wear detection and classification

Predictive maintenance alerts based on usage patterns

Deviation tracking against tool specifications

Heat map visualization of wear zones

Historical performance and failure trend analysis

Integration with ERP and CMMS for automated scheduling

Benefits

Improved product quality and reduced field failures

Extends tool life and reduces unplanned downtime

Improves production quality by eliminating tool-induced defects

Lowers cost of tool replacement and rework

Supports digital transformation through smart analytics

Enhances compliance and traceability in regulated environments

Industries Served

Automotive and Transportation

Aerospace & Defense Manufacturing

Automotive Component Production

Precision Machining & Tooling

Metal Fabrication

Plastics & Injection Molding

Electronics & Semiconductor Fabrication

Integrations and Compatibility

Manufacturing Systems : CNC controllers, ERP platforms, SCADA systems

Protocol Support : OPC-UA, MQTT, Modbus

Compatible Sensors : Kistler, Keyence, National Instruments, Mitutoyo

Enterprise Platforms : SAP, Oracle NetSuite, IBM Maximo

Applications

Cutting tool condition monitoring in CNC operations

Die and mold integrity inspection in forming and injection molding

Punching tool usage analysis in sheet metal fabrication

Wear pattern analysis in forging and stamping operations

Micromachining and high-precision tool diagnostics

Relevant Industry Standards

ISO 8688-2

ASME B5.54

ANSI B11.19

CSA Z1006

ISO/TS 13399

OSHA 1910 Subpart O

Case Studies

United States – Michigan

An automotive powertrain manufacturer in Michigan deployed our Tooling Wear and Tear Analysis solution across 12 CNC lines. Using edge analytics and thermal sensors, the company identified pre-failure indicators on drill bits and saw a 32% increase in tool life, while reducing scrap rate by 18%.

United States – Illinois

In Illinois, a high-volume stamping plant used our real-time wear monitoring platform to track punch degradation. Automated alerts led to optimized die replacement schedules, improving uptime by over 20% and avoiding costly breakdowns during peak runs.

Canada – Quebec

A precision tool and die shop in Quebec adopted our optical wear scanners for mold inspection. Coupled with cloud-based analytics, the system detected micro-fractures invisible to the naked eye, helping meet stringent aerospace manufacturing tolerances and win a multi-year OEM contract.

Ready to ensure your products meet the highest standards of quality and performance?

Contact us today to learn more about how Manufacturing EnviroTest’s tooling wear and tear analysis can help you minimize downtime and maximize tool performance.