Product Quality & Performance Testing in Mechanical Integrity Testing

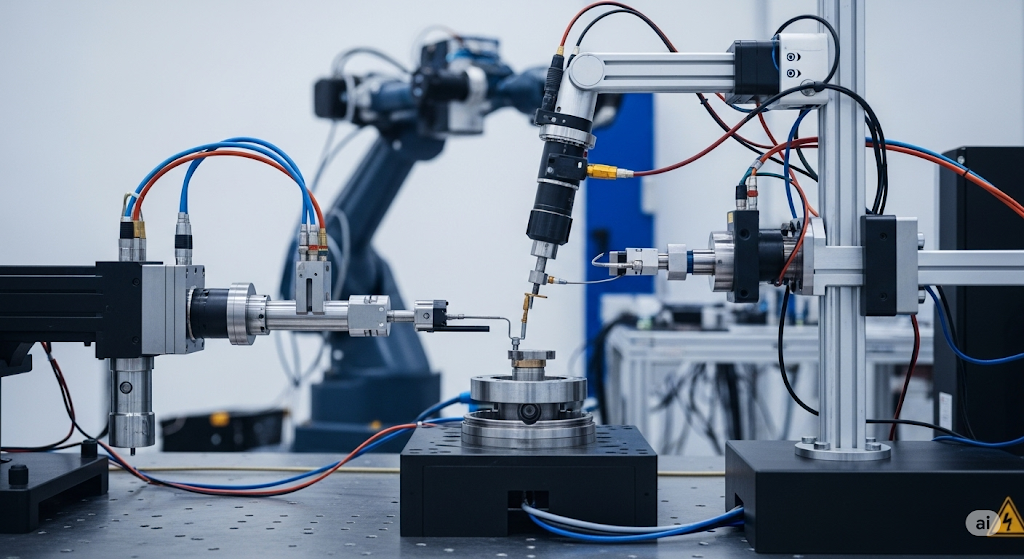

Verify structural soundness and mechanical performance with precision testing systems from Manufacturing EnviroTest.

Overview

Mechanical Integrity Testing for Product Quality & Performance Testing is a crucial solution provided by Manufacturing EnviroTest to assess the structural durability, strength, and performance of products under mechanical stress. Our testing systems simulate static and dynamic loads, pressure, torsion, impact, and deformation to reveal vulnerabilities, ensure safety, and validate design integrity before mass production.

At Manufacturing EnviroTest, headquartered in Seattle, WA, we help manufacturers across North America prevent mechanical failures through intelligent, data-driven testing systems backed by rigorous QA, innovative R&D, and expert consultation. We proudly collaborate with GAO Tek and GAO RFID to expand integration and enhance the technological capabilities of our mechanical integrity solutions.

Hardware

Load frames with static and fatigue testing capabilities

Use Hardness Testers from Structural Testers to validate mechanical strength during fatigue assessments.

Pneumatic, hydraulic, and electromechanical actuators

Employ Industrial & Asset Monitoring Sensors from IoT Sensors to monitor actuator pressure and load stability.

Impact hammers, drop testers, and torsion test machines

Integrate Vibration Meters from Structural Testers to measure force and dynamic response in shock or torsion events.

Pressure vessels, fixtures, and strain measurement sensors

Apply Pressure & Process Calibrators from Environmental Test Instruments to ensure precision in load and pressure readings.

Core Components

Software

Control software for automated stress-strain test sequencing

Deformation tracking with high-resolution data logging

Real-time force/displacement graphing and failure point detection

Material modeling and fatigue lifecycle simulation tools

Cloud Services

Time-stamped archiving of mechanical test results

Remote access to live or historical testing sessions

Predictive maintenance and trend analysis via AI/ML

Integration with digital twin models and design platforms

Key Features and Functionalities

Simulates real-world static and dynamic mechanical loads

Enables compressive, tensile, torsional, and flexural tests

Detects micro-cracks, stress concentrations, and material fatigue

Supports accelerated stress testing and destructive testing

Auto-generates failure mode reports with pass/fail logic

Syncs mechanical data to CAD/PLM systems for redesign feedback

Benefits

Ensures compliance with mechanical safety and strength standards

Prevents product failure through early-stage design validation

Optimizes structural designs for lightweighting and durability

Enhances brand trust with validated mechanical performance

Reduces warranty costs and field service incidents

Speeds up go-to-market with reduced redesign cycles

Industries Served

Automotive & Transportation

Aerospace & Aviation

Consumer Goods Manufacturing

Construction & Civil Engineering

Medical Equipment

Industrial Machinery

Integrations and Compatibility

Design & Simulation Tools : SolidWorks Simulation, ANSYS, Abaqus

Data & Protocol Systems : Modbus, CAN bus, RS-485, Ethernet

Cloud & ERP Platforms : AWS IoT, Microsoft Azure, SAP, Oracle Cloud

Control Frameworks : NI LabVIEW, Python, MATLAB

Applications

Load-bearing automotive components (e.g., chassis, frames)

Aerospace structural panels and fasteners

Consumer appliance housing and joints

Construction materials and structural connections

Pressure-rated enclosures and piping systems

Relevant Industry Standards

ASTM E8

ISO 6892

CSA S16

ANSI/AISC 360

ASME BPVC Section VIII

ISO 10993-5

Case Studies

United States – Ohio

A heavy machinery OEM in Ohio used our system to validate the structural welds in forklift chassis. Through fatigue and torsion testing, a failure point was uncovered in the crossbeam section, prompting a design upgrade that led to a 27% increase in lifespan and reduced warranty returns.

United States – Texas

An energy equipment manufacturer in Texas adopted our impact and pressure testing systems to certify mechanical enclosures used in oilfield environments. They identified gasket deformation under repeated impact cycles and introduced a new sealing material that passed UL mechanical integrity requirements.

Canada – Ontario

A Canadian medical device company in Ontario implemented our mechanical integrity platform to assess the load tolerance of a portable patient lift. Testing exposed fatigue stress on joint components, leading to reinforcement that cleared both Health Canada and FDA guidelines on the first submission.

Looking to guarantee the mechanical integrity of your products with precision and confidence?

Contact us today to learn how Manufacturing Envirotest can help you achieve new standards of strength, safety, and performance.